What is the heat affected zone (HAZ?)

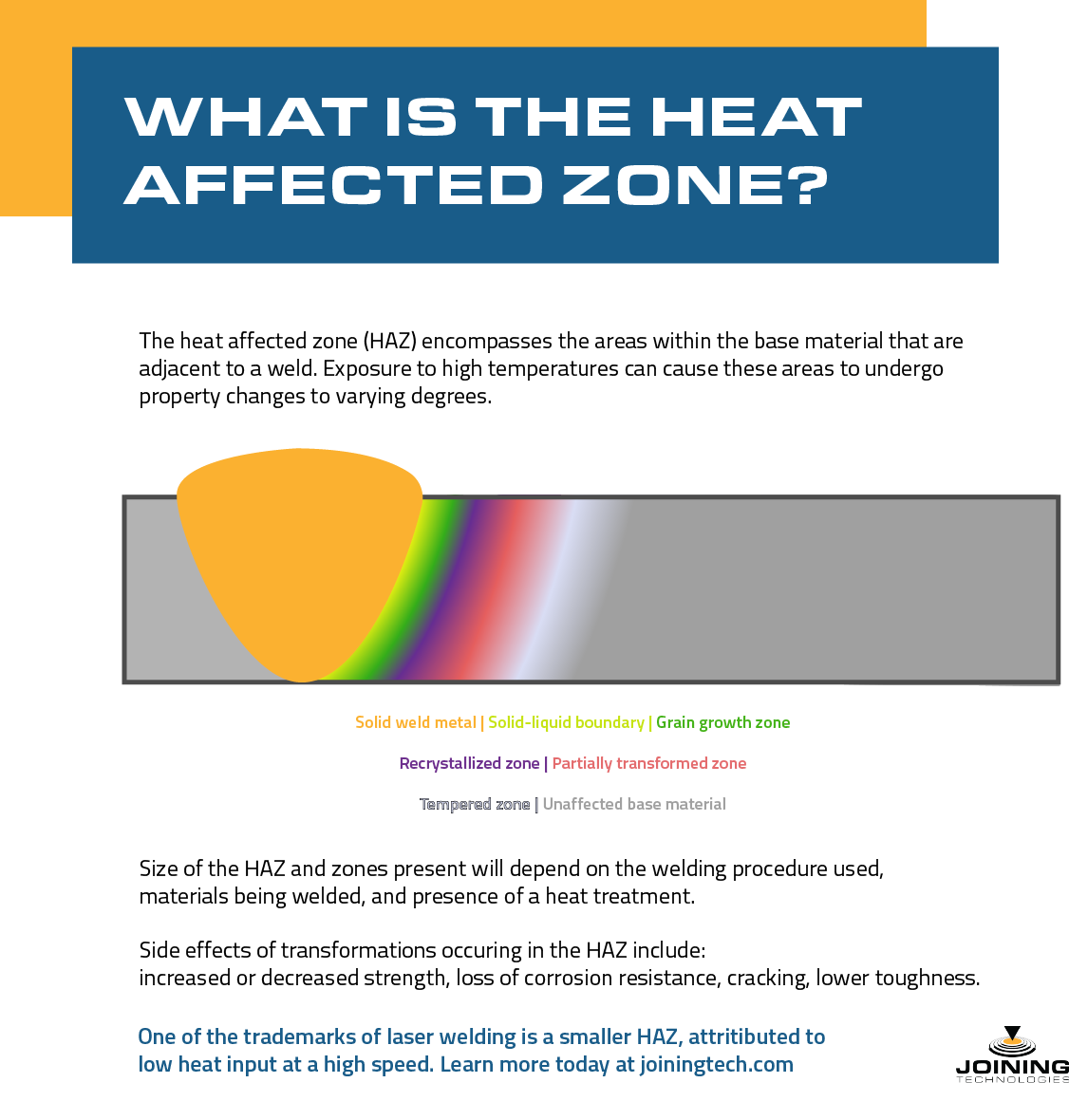

The heat affected zone is an area of the base material that hasn’t melted during the welding process, but has undergone changes in material properties as a result of its exposure to high temperatures.

Where does the heat affected zone occur?

Heat affected zones form adjacent to the weld. The following factors influence the size of the HAZ:

- Heat input

- Duration of exposure to heat

- Thermal diffusivity of the base material

Long cool down times mean larger HAZs. Laser welding, for example, uses a very low heat input, which means the components being welded will cool faster, and the HAZ is smaller.

How can you evaluate a heat affected zone?

Often, heat tint is visible and can indicate the temperature the material reached. Light yellow is the coolest (550° F) and dark blue is the hottest (1,100° F).

However, these colors are visible because of oxidation. Factors like surface condition, contamination and oxygen availability can affect the appearance of a heat affected zone. Materials with a high amount of chromium won’t display intense heat tint, because they’re resistant to oxidation.

While the heat tint is the most visible indicator that a material has undergone change, other chemical and metallurgical changes can occur within the HAZ. They include:

- Surface Nitriding – increased hardness, and decreased weldability.

- Corrosion – caused by precipitation of chromium carbides near grain boundaries. Without chromium content of 10.5%, steel loses it’s “stainless” quality.

- Hydrogen embrittlement – hydrogen gas diffuses into the molecular structure of the material, producing cracks.

- Phase changes – Austenitic steel can become Martensitic after exposure to extreme heat, becoming harder and more brittle, or becoming generally weaker.

Are there ways to reverse the molecular changes?

While we can never eliminate the creation of a heat affected zone entirely, we can deploy a pre-weld or post-weld heat treatment. Using a heat treatment can help restore material properties lost while welding.

If you work with Joining Technologies, our engineers and technicians will develop the best strategy for your specific project to ensure the best result possible.

Looking for a partner in precision welding?

Let us guide you through the options.