Laser welding firearms might be new, but firearms manufacturing in New England is something of a tradition.

In 1777, George Washington chose Springfield, MA to be our budding nation’s first arsenal. Headquartered in this region are companies steeped in the history of firearms; Smith & Wesson, Savage Arms, Sturm & Ruger, O.F. Mossberg & Sons, Colt, and countless others. Many of the United States’ first firearms manufacturers are still in operation today and continue call New England their home.

A complete supply chain has grown around these manufacturing leaders. As of May 2022, a total of 550 firearms manufacturers (FFL classes 6 – 11) exist across MA and CT. 206 of them are SOTs. You’ll find no shortage of companies, like Joining Technologies, that help produce firearms, whether it’s by forging, machining, stamping, or laser welding firearms components that become part of the final assembly.

What does it mean to be a firearms manufacturer?

Joining Technologies maintains a Code 07 Federal Firearms License. This is designated for a “manufacturer of firearms other than destructive devices.” The Code 07 FFL is separate from those possessed by dealers, importers, and antique collectors. However, anyone who is “engaging in the business of” firearms needs to acquire and maintain a license.

Joining Technologies is also a Special Occupational Taxpayer (SOT). Having an SOT expands upon the Code 07 FFL, allowing manufacturers to commercially manufacture and handle NFA items, such as suppressors. Manufacturers must also observe state laws surrounding firearms, which may further regulate working with NFA items.

Quality standards for firearms manufacturers

In addition to obtaining the proper clearances and documentation, it’s also incredibly important to adhere to quality standards when laser welding firearms. Firearms can be dangerous even when they are functioning correctly. An unsafe firearm can lead to disastrous worst-case scenarios.

After laser welding firearms components, Joining Technologies performs the following quality inspections:

- Cross-section to observe the depth of penetration.

- Components must pass pull and torque tests for strength.

- FPI (Fluorescent Penetrant Inspection) to locate breaks in the material’s surface, if any.

Benefits of laser welding firearms

With more than one way to join materials, why choose laser welding?

- Small heat affected zone helps preserve metallurgical structures.

- Highly repeatable process guarantees quality and consistency.

- Laser welding is ready for automation.

- Great for high volumes.

- Parts of all sizes and shapes can be laser welded.

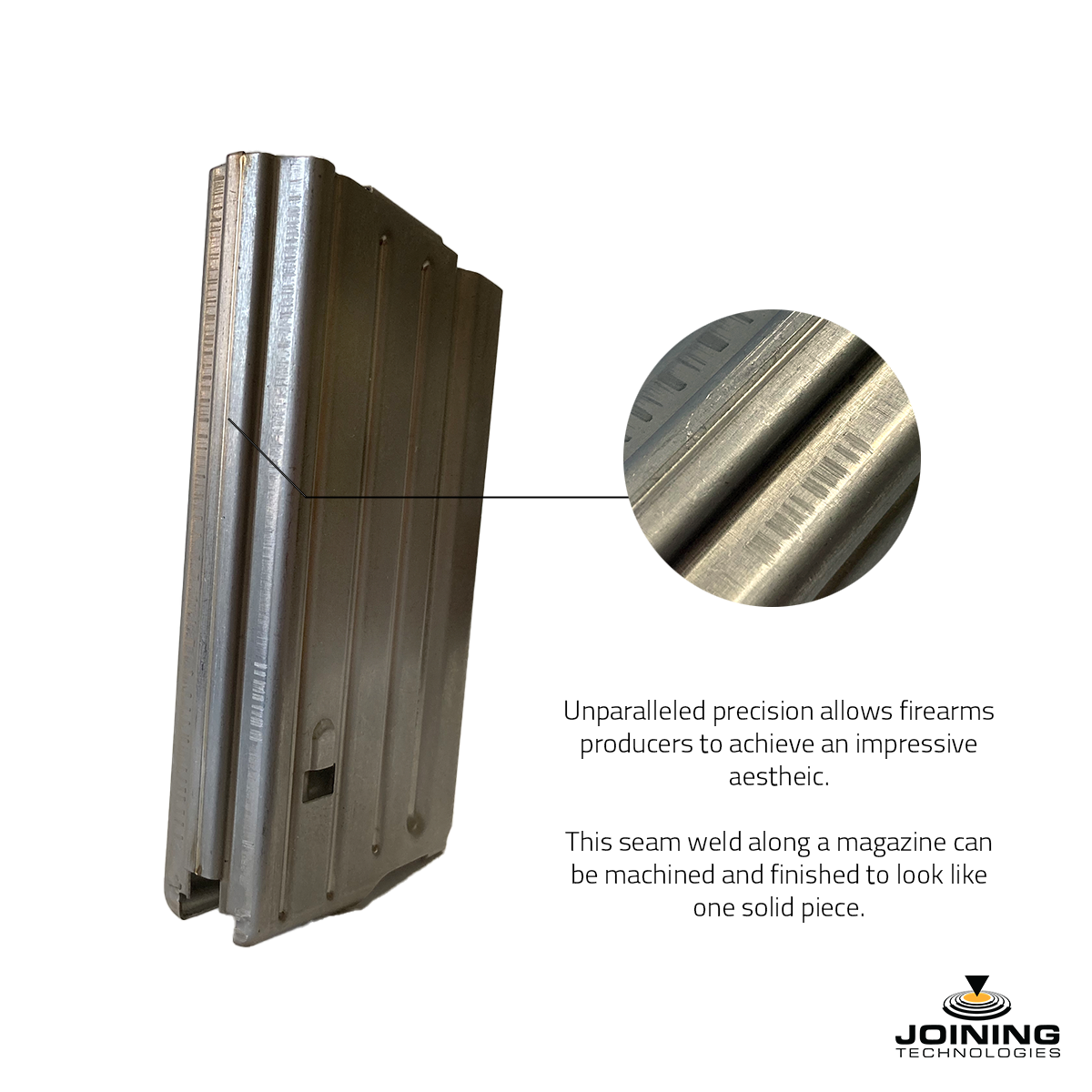

- Cosmetic appeal is superior to other welding methods.

While laser welding is our flagship service, resistance welding provides several of the same benefits.

For more information, check out our “Laser Welding Vs.” article, or Ask an Expert!