Joining Technologies | 9/27/2024 | 5 Min Read:

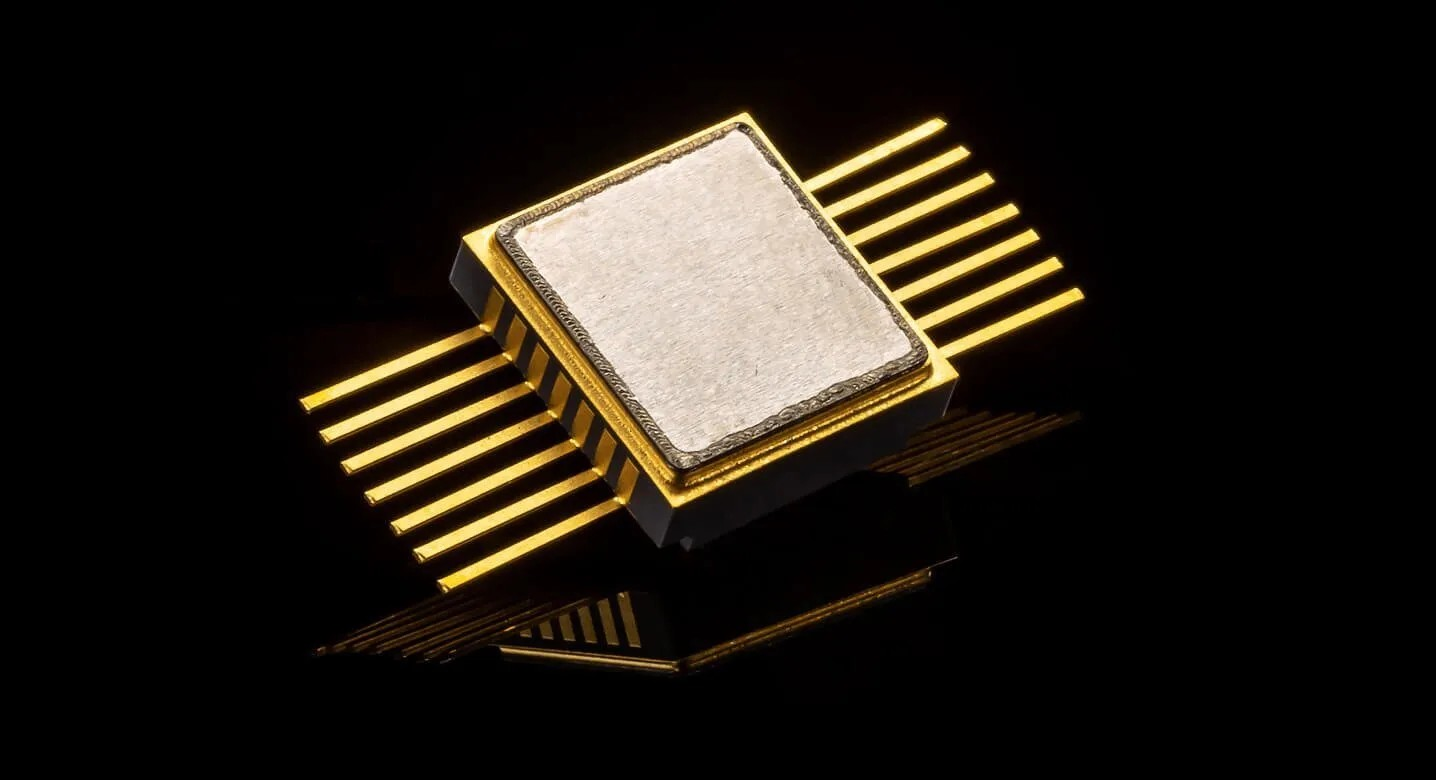

In today’s world, the need to protect sensitive components from external environments is more critical than ever. Whether you’re dealing with electronic devices, medical equipment, or aerospace systems, ensuring that no air, moisture, or contaminants can penetrate the enclosure is essential. This is where hermetic sealing comes into play.

Hermetic sealing is the process of making an object airtight to prevent the flow of gases, liquids, and other external elements into or out of the system. Derived from the Greek god Hermes, known for his ability to contain the elements, hermetic sealing has evolved to become a crucial component in numerous industries.

What Exactly is it?

Hermetic sealing creates an impermeable barrier, effectively protecting what’s inside from any external influence. A hermetic seal ensures that no gas, moisture, or contaminants can pass through, regardless of the surrounding conditions. This is achieved through precise engineering and materials, often using processes such as welding, brazing, or advanced adhesives.

The goal of hermetic sealing is to provide a lasting, airtight enclosure that can withstand extreme conditions—be it high pressure, temperature fluctuations, or exposure to corrosive elements.

How Does it Work?

To achieve an airtight seal, several methods and materials are used. Here are the most common ones:

-Welding

Welding is a highly reliable method for hermetic sealing, especially in industries like aerospace and medical devices. Techniques like TIG welding (GTAW) and laser welding ensure that metals fuse together to create an airtight bond. Welding is ideal for applications that require strength and long-term reliability.

-Brazing

Brazing is similar to welding but uses a filler metal that melts at a lower temperature than the base metals. This creates a strong bond without melting the core materials, often used in electronics and industrial applications where precision is essential.

-Glass-to-Metal Sealing

In some cases, especially in electronics, hermetic seals are created by bonding glass to metal. The differing thermal properties of glass and metal allow for an airtight seal when carefully heated and cooled. This method is common in the production of vacuum tubes, sensors, and medical equipment.

-Advanced Adhesives

For less extreme environments, adhesives can be used to form hermetic seals. These advanced adhesives are specially formulated to create impermeable barriers against moisture and gases, often used in consumer electronics and certain medical applications

The Importance of Hermetic Sealing

Hermetic sealing is essential in a wide range of industries, where protecting components from environmental exposure can be the difference between success and failure. Here are some of the most significant reasons why hermetic sealing is important:

-Preventing Contamination

In industries like pharmaceuticals, food packaging, and medical devices, contamination can have devastating effects. Hermetic sealing ensures that no contaminants such as dust, moisture, or microbes can enter the enclosure, maintaining sterility and preserving product integrity.

-Enhancing Durability

Hermetic seals protect components from environmental wear and tear, extending the lifespan of the products they enclose. In harsh environments, such as in the aerospace industry or underwater exploration, a hermetic seal ensures that sensitive systems can withstand extreme conditions.

-Ensuring Safety

In certain applications, a leak can be catastrophic. For example, in aerospace fuel systems, even a small breach in a seal could lead to dangerous leaks, risking the entire system. Hermetic seals ensure that gases and liquids stay contained, reducing the risk of accidents and ensuring the safety of both equipment and personnel.

-Improving Performance of Electronic Components

Electronic devices, especially those used in critical fields like telecommunications, aerospace, and military applications, rely on hermetic sealing to function properly. Exposure to humidity, air, or corrosive gases can degrade the performance of sensitive electronics. Hermetic enclosures keep these elements out, ensuring that circuits, sensors, and other components continue to operate reliably.

-Enabling Space Exploration

In space exploration, where equipment must endure the vacuum of space, drastic temperature swings, and cosmic radiation, hermetic sealing is non-negotiable. Every system aboard a spacecraft, from its fuel tanks to its communication devices, relies on airtight seals to function in these extreme environments.

Joining Tech Now Offering Hermetic Sealing

In conclusion, hermetic sealing is crucial for protecting sensitive components in industries ranging from aerospace to electronics. By ensuring airtight protection against environmental factors, it enhances durability, safety, and performance. At Joining Technologies, we offer advanced hermetic sealing solutions, primarily using laser welding to meet the demanding needs of our clients. Our expertise ensures that your systems remain secure and reliable, even in the most challenging environments.

Have Some Questions?

Let us answer them by clicking the button below!