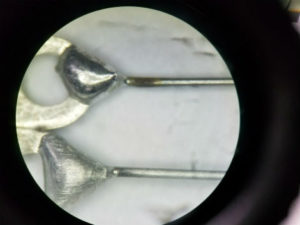

| This image shows a part with corrosion (top) and without (bottom). |

A recent issue with a soldering process for a customer has been the focus of our attention here at Joining Technologies for quite some time. Since it turned out to be a good learning experience, we thought it was worth sharing to explain issues that intermittently arise when soldering these types of assemblies.

The process I’m speaking about involves soldering a 26 gauge, bright soft steel wire to a flat solder terminal made of tinned copper. Overall, the process is very sound with excellent bonding and visually acceptable solder joints. However, we were finding corrosion and oxidation on the assemblies, which rendered some of the parts to be non-conforming. Since the corrosion occurred infrequently, a deeper look at the process was required.

We dissected every step of the process and eventually found that we were using a hydrochloric acid-based flux. This is something that never crossed our minds, but obviously sheds light into why we had the issues of corrosion and oxidation. Even after following the manufacturer’s instructions for neutralizing the flux, the corrosion was still evident.

Upon calling tech support for the soldering flux manufacturer, we quickly found out that not all flux is created equal! After explaining our application, a tech expert recommended a bromide-based flux as a replacement option, since we were dealing with stainless steel. It’s also important to mention that certain soldering fluxes work better with soldering torches vs. soldering irons. We use the soldering torch in our assembly process.

Post-cleaning or rinsing is required for all types of flux. Always follow the manufacturer’s rinsing instructions for the specific type of flux used, as the expert noted that flux is not supposed to be left on any material post-process. The best time to rinse the materials of flux is immediately after soldering. This is a very important part of the process that should not be overlooked.

The bottom line is, it’s important to know your material types as well as the difference between torch soldering and iron soldering! Your choice of flux and a successful soldering process will depend on these factors.

Questions? Contact us at 860.653-0111