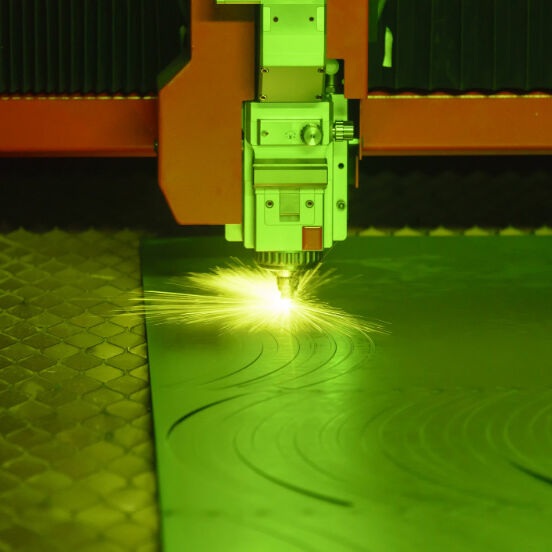

What is Green Laser Welding

Welding reflective materials such as copper or aluminum with infrared lasers is a frustrating endeavor. The process takes a long time, and is rather inefficient overall. In fact, approximately 90% of the energy from an infrared laser will bounce off of aluminum as you’re trying to weld it. So, what to do? Look no further than green laser welding systems!

With green laser welding (GLW), these problems are a thing of the past.

The Benefits of Green Laser Welding

Green Laser Welding offers:

- Shorter wavelengths, roughly half of a typical infrared laser

- Quicker and more efficient, since more of the green laser’s energy is absorbed by the component

- Create uniform, repeatable results

- Low spatter formation

Industries Serviced

- Energy

- Battery

- Any copper or aluminum-based industries

Green Laser welding is material dependent and is often well suited for batteries, battery cases, sensors, aerospace parts, and more.

Learn More

Reimagine your welding capabilities with Green Laser Welding – a transformation in precision, efficiency, and cost savings. Fill out the form below to get started!

Contact us for a quote.

READ OUR BLOG

WHAT WE DO

Joining Technologies’ state-of-the-art services include precision laser welding, electron beam (EB) and gas tungsten arc welding (GTAW), machine shop services and supply chain management. All along the way, our quality control system will be an integral part of your project’s life journey at Joining Technologies.